Non-Destructive Testing Services

Different Tubes

|

Eddy Current,

|

Data Analysis

Depending on your requirements, our NDE analysts can provide on-site or remote data interpretation, utilizing

the most advanced software for Eddy Current, Remote Field and Near Field Testing. Conco analysts will identify defects in your condenser or heat exchanger tubing and provide a comprehensive report of their findings. We can even assist you in theestablishment of a non-destructive testing program. This allows Conco to trend the growth of previously identified damage within the condenser or heat exchanger. It also allows Conco to monitor for any new damage mechanisms that may occur during the operating cycle. This is part of a preventative maintenance program that Conco can help establish and maintain. |

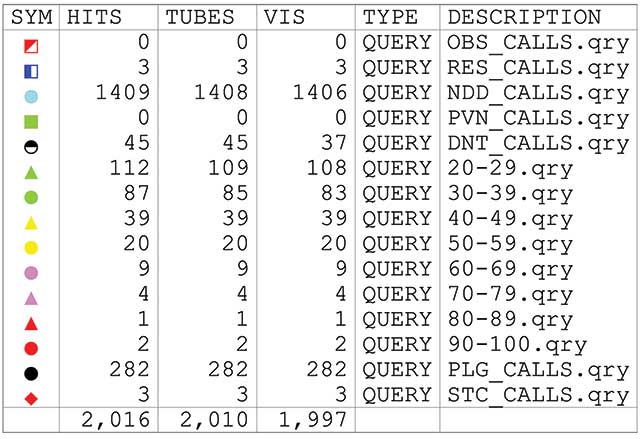

Tubesheet Mapping

This service provides an at-a-glance summary of condenser or heat exchanger condition. Upon completion of a comprehensive non-destructive testing evaluation, Conco can create a multicolor tubesheet map for graphic illustration of tube wall condition. The overall condition of the condenser or heat exchanger and any developing trends are obvious as

each tube’s condition is represented by a different color or symbol. |